Receiving hoppers - Falcon

Receiving hoppers - Falcon

Crop handling

Description

Fast storage, gentle handling

The AVR receiving hoppers ensure your crop to be handled in a fast and effective, as well as a potato-friendly manner. The machine is available in several versions and with different roller variations, so that you can virtually custom-tailor your machine. The different possibilities for configuration and the numerous options, make it the ideal machine for middle to big potato (processing) companies.

Gentle and flexible bunker

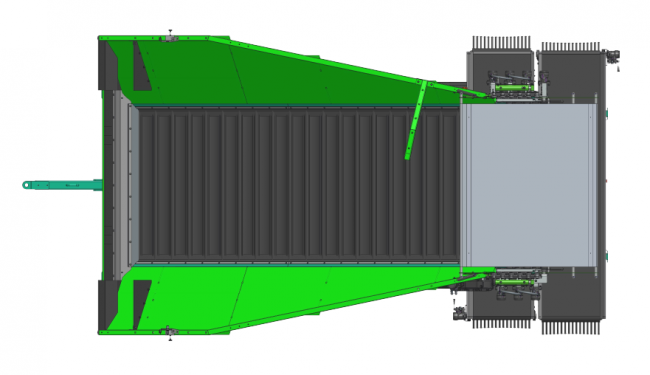

Different models can be chosen for the reception hoppers. An articulation at the front or back of the bunker can be opted for. Furthermore, the bunker is equipped with a unique bunker floor (100% product-friendly) with an increased transportation effect.

Potato friendly bunker floor

The hopper floor is standard equipped with a horizontal nod after the inclining part. This helps to break the solid flow of the product and ensures a better distribution and a constant flow of the product to the cleaning rollers. Therefore having an even higher sieving/cleaning capacity of the roller unit.

The roller unit can be customized with extra cleaning options for each type of cleaning rollers, which help to keep the rollers clean and optimize cleaning capacity under tough conditions.

(Picture: Falcon 1800 hopper floor)

All of our crop handling and storage equipment is manufactured in our production facility in Veendam (The Netherlands). Click here for a look behind the scenes.

Specifications

Receiving hoppers - Falcon

- User friendly operating screen (touch) and numerical keypad with clear layout

- Soft potato friendly hopper floor

- Soil and product discharge belts with height and lateral adjustment

- Robust frame with heavy chains for the hopper floor

- Fall height between the hopper floor and roller unit is adjustable, so it can be kept to a minimum

- Roller unit with adjustable angle

- The discharge conveyors are fixed to the roller unit to keep the discharge conveyors always in the correct position

- Standard equipped with PU spiral rollers that guarantees a soft roller unit. Optional with possibility to clean the rollers of sticking dirt

- Other types of cleaning rollers are available also with optional roller cleaning

- Small cleaning rollers of 90 mm (more gentle for potatoes)

- Standard equipped with line control

- The intake height is hydraulically adjustable

- Optional intake plate attachment

| Falcon 1800 | Falcon 24-45 | Falcon 24-60 | |

| Content (m³) | 10.90 | 12.60 | 18.40 |

| Entry width (m) | 3.18 | 3.30 | 3.30 |

| Floor width (m) | 1.65 | 2.40 | 2.40 |

| Floor length (m) | 4.00 | 4.50 | 6 |

| Variable floor speed (m/sec) | 0.5-6.5 m/min | 0.5–6.5 m/min | 0.5–6.5 m/min |

| Number of rollers | 6 | 8 (+1) or 15 (+1) | 8 (+1) or 15 (+1) |

| Roller spacing (mm) | 5-45 | 5-55 | 5-55 |

| Roller speed (continuous) (RPM) | 30-180 | 60-160 | 60-160 |

| Roller set width (m) | 1.85 | 2.40 | 2.40 |

| Soil cross conveyor width (m) | 0.65 | 0.80 | 0.80 |

| Crop cross conveyor width | 0.65 | 0.80 | 0.80 |

| Tyre size (p) | 0.0/75-15.3 18PR 6/161/2015 | 12.5/80-15.3 14 ply | 12.5/80-15.3 14 ply |

| Capacity (t/h) | 80 | 120-150 | 120-150 |

| Power voltage (V) | 400 | 400 | 400 |

| Total power consumption (kW) | 7.5 | 12.60 | 12.60 |

Download Center

- Download Brochure AVR Falcon_Chinese

- Download Brochure AVR Falcon1800_Chinese

- Download Brochure AVR Falcon1800_English

- Download Broszura AVR Falcon1800_Polish

- Download Broszura AVR Falcon_Polish

- Download Brochure AVR Falcon_Russian

- Download Brochure AVR Falcon1800_Russian

- Download Brochure AVR Falcon_English

- Download Brochure AVR Crop handling equipment_English

- Download Brochure AVR Crop handling equipment_Spanish

- Download Brochure AVR Crop handling equipment_Polish