Spirit 6100

Spirit 6100

Harvesters

Description

The Spirit 6100 is a 1-row offset potato harvester equipped with a six ton bunker. This smallest member of the Spirit family has everything you need for a quality harvest.

Over the years, the Spirit series has built a strong reputation for potato-friendliness and capacity. The Spirit 6100’s unique harvesting and separation system provides a very potato-friendly harvesting process - it’s all about your precious potato. AVR has therefore developed a smooth product flow with minimal drop heights, as few directional changes as possible and a flat picking-off table. These features make it the ideal machine for harvesting early potatoes for the retail market. The 6-ton bunker and wide channel also ensure ample capacity.

Single row, large capacity

The Spirit 6100 is a single row bunker potato harvester with a large capacity. It can transport 6,000 kg in combination with the bunker optimizer. This substantially increases the capacity of the machine, since less time is spent discharging.

Easy operation with CAN-bus

The machine is driven by a CAN-bus system, like our trailed 2-row harvesters and our self-propelled harvesters. With this CAN-bus system the machine can be operated with a joystick and via an operating screen, to make adjustments. Some control functions can be added, as well as a self-diagnostic. As such, maintenance gets easier.

Specifications

Spirit 6100

| Spirit 6100 | |

| Rows | 1 |

| Inter row distance (cm) | 75 or 90 |

| Dimensions (l x w x h in m) | 8.82 x 3.00 x 3.70 |

| Weight (kg) | 6.500 |

| Bunker capacity (tons) | 6 |

| Maximum discharge height (m) | 4.10 |

| Required power (hp) | 66 kW / 90 hp |

| Drive | Mechanic |

| Offset/in-line | Offset |

| Oil flow (on 180 bar) (l/min) | 60 |

- Wide 80 cm channel

- Large platform around picking-off table with room for up to 6 people

- Operation by means of a structured display and joystick (can-bus system)

- Large bunker

- Large wheels, wide tires -> low soil pressure, easy machine pulling

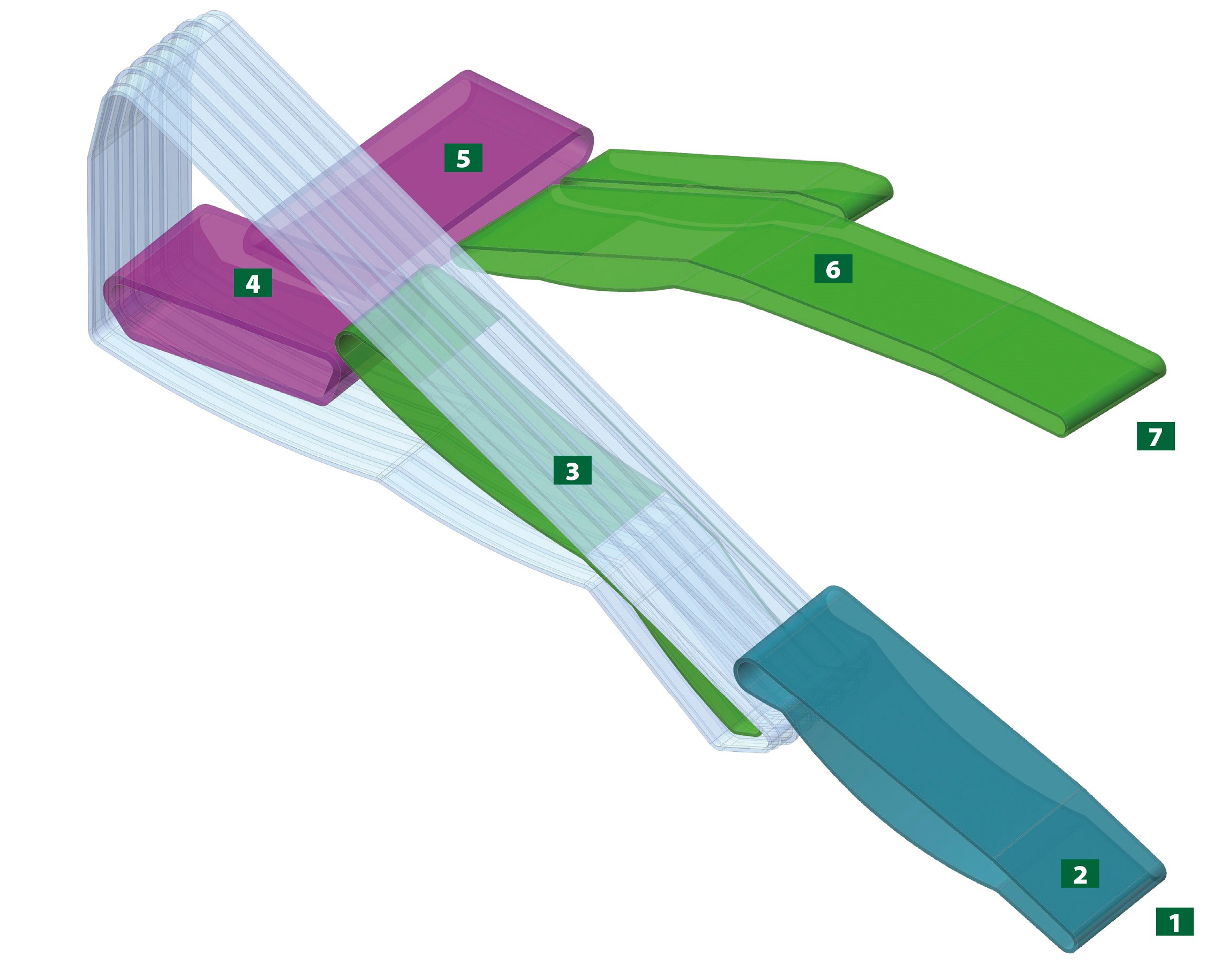

- The potatoes are taken in by the AVR digger unit. This digger unit features large haulm intake rollers, plastic diabolos that hold the rows together, a simple ce ntral depth adjustment and an open construction.

- The 80 cm wide digging web guarantees high sieving capacity.

- The combined second sieving web and haulm web provides potato-friendly haulm separation and helps the potatoes move up the inclination. Haulm and weeds are easily separated, even in difficult conditions (such as green haulm).

- The potatoes are carried to the first pintle belt where the loose dirt, small clods and haulm disappear under the retaining roller and are removed from the machine.

- The potatoes are directed by the retaining roller to the second pintle belt (the transversal pintle belt), with the rotary comb mounted above. Here, clods, stones and, if desired, undersized potatoes are removed and the product flow is evenly spread across the picking-off table. The clods and stones are sent to a discharge belt.

- A final inspection can be performed by four people on the picking-off table and there is room for two more people at the discharge belt.

- The potatoes are then sent to the 6-ton bunker. An optional fall breaker/box filling system offers the possibility to fill boxes directly.

- Gearbox: 2 web speeds

- hydraulic jack

- high pressure filter and manometer

- joystick (CAN BUS control) + intuitive control screen

- independent hydraulic system to drive the 2 pintle belts, retaining roller and rotary comb

- wheels 550/60 - 22.5

- hydraulic steering wheels

- hydraulic drawbar steering

- hydraulic level control of machine

- picking-off table for up to 5 people

- electro-hydraulic adjustment of pintle belt inclination

- 6 ton bunker capacity, impact-absorbing strips mounted on bunker floor

- wheels 600/50-26.5 (not suitable for inclines)

- retaining rollers above transversal pintle belt instead of rotary comb

- 4 grading rollers in picking-off table with adjustable opening

- stone bunker under picking-off table

- automatic land leveling

- bunker optimiser with rubber flap

- fallbreaker at bunker end for crate filling (mech. or hydr.)

- Bigbag system

- automatic swan neck in picking-off table

- additional rows of haulm retainers on haulm web

- auto. resetting of the steering wheels

- auto. row following

- auto. electro-hydr. counter pressure regulation on the digging unit

- cameras

- agitator hydraulic raise/lower

- onion picking unit