Puma 4.0

Puma 4.0

Harvesters

Description

To help you face your current farming challenges, you can confidently rely on AVR's self-propelled harvester. Meet the world leader in the four-row self-propelled range: the PUMA 4.0. A heavy-duty, reliable and easy-to-operate machine that is extremely potato-friendly. Even in wet weather conditions, this gentle giant will soldier on. Your Puma can also be connected to the web. This will enable you to capture your machine data on the AVR Connect platform to work even more efficiently.

Easy operation

The Puma 4.0 is the ultimate in user-friendliness, as it is operated with the aid of a well-designed touchscreen, the AVR joystick and a quick-select rotating button. The AVR operating panel is ultrabright and therefore easily legible in all circumstances. It is capacitive and tactile, just like a smartphone. The fast processor ensures rapid response, which promises further opportunities for future automation and IoT applications. The screen has retained its well-known intuitive AVR look and feel. The myriad of automatic functions, an optimal view of the digging unit and a large number of cameras mean that you can keep your full attention with the harvesting process.

Protecting the soil structure

The Puma 4.0 is a heavy-duty machine that, despite its 23,500 kg, still remains a lightweight in its class. The engine's position has been carefully designed so as to counterbalance the elevator. This optimal weight distribution guarantees an equal load on the tires and a minimum amount of track forming.

Design in the field

The Puma is extremely manoeuvrable given its compact lightweight construction and its enormous steering radius (50° at the front and 20° at the rear). All the Puma parts are stored neatly behind easily opening doors.

Maximum intake

The harvesting channels are 1,450 mm wide for the model with 4x75 cm rows (or 1,550 mm for 4x90 cm). With the pulled non-sticking plastic diabolos, the pulled cutting discs and the large haulm intake rollers, the digging unit ensures an unfailing and very reliable potato intake. The ridge pressure can be adjusted under all circumstances, which means the ridges remain intact and all potatoes are removed from the soil.

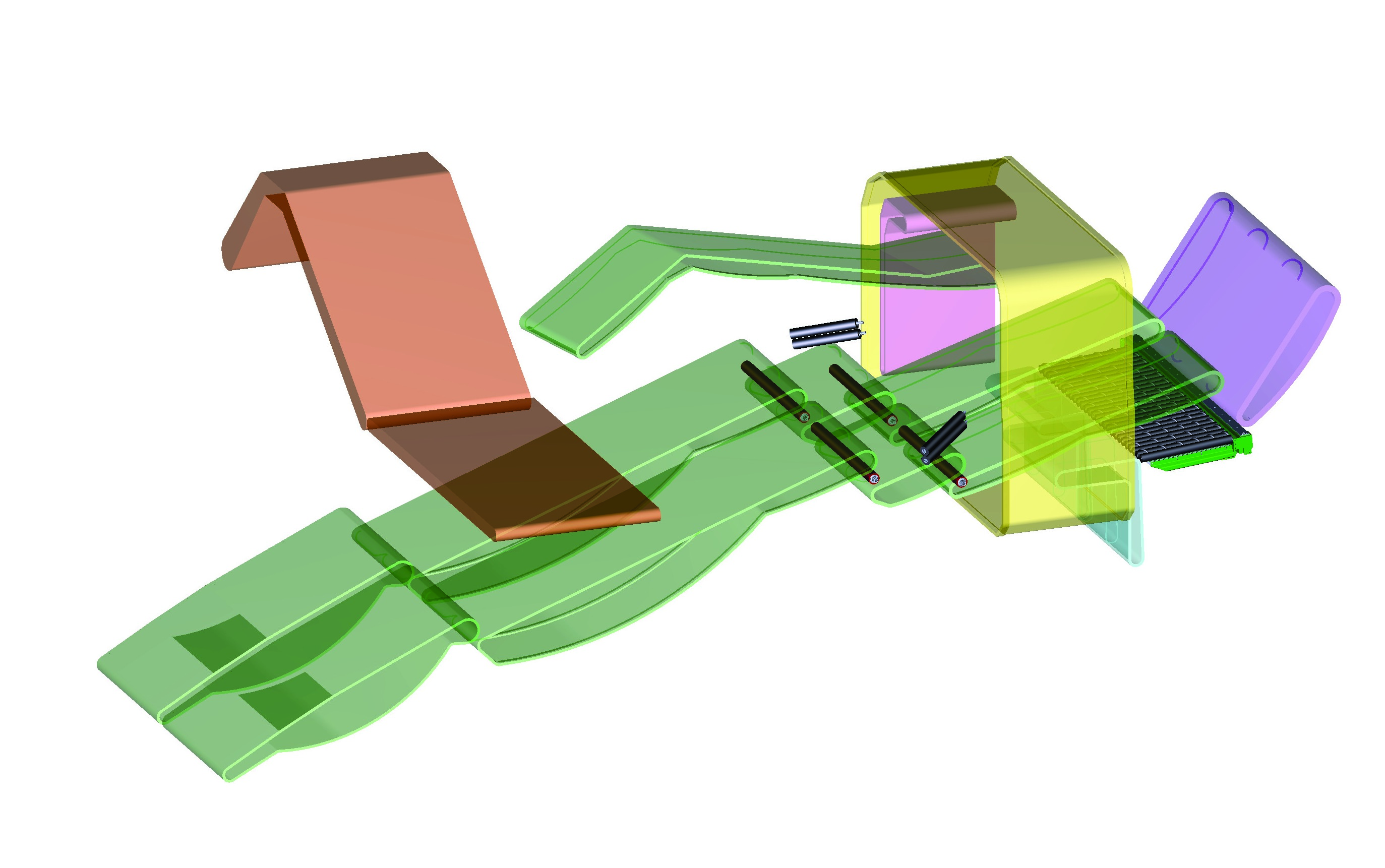

Varioweb cleaning module

The patented Varioweb consists of a standing pintle belt with an axial roller set underneath. A unique feature is the ability to infinitely set the product flow volume that travels across the axial rollers from the cabin: from 100% when intensive cleaning is required to 0% when hardly any cleaning is needed. This is done by moving the axial unit forward or backward.

Ensure an optimal use of your Puma 4.0! In an instant, the digging unit can be converted for harvesting carrots or picking up onions.

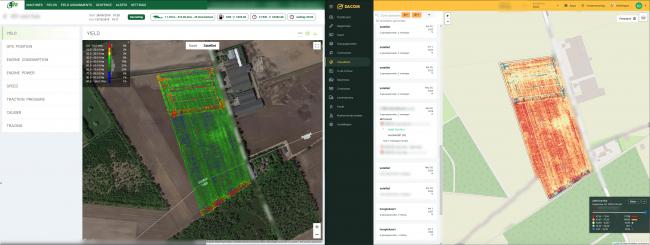

AVR Connect: next-level harvesting

This machine can be connected to the internet which allows for machine data to be transmitted to AVR Connect.

AVR Connect is an online reporting tool for your machine activities, and an online collection system for all your machine data, both on and off the field.

AVR Connect offers you more data and consequently a more effective use of your machine and resources.

- Applying precision farming techniques makes your work more efficient, leading to lower costs.

- Statistics provide insight into improvement opportunities.

- Easy access using your e-mail address and password.

- Personal, safe and user-friendly platform.

AVR Comfort Drive on Puma 4.0 ACC

With the All Conditions Control digging unit, users can harvest either using diabolos or using probes, i.e. without exerting any pressure on the ridge. The advanced control technology responsible for depth control when harvesting using probes, the AVR Comfort Drive, works with great accuracy, which means the digging unit, and as a consequence the whole machine, can be operated more stable than ever.

Immediate advantages for the user:

- More comfortable for the driver

- The control performs very well under all circumstances (also in case of spray tracks, on inclined terrains, etc.), meaning manual intervention is no longer necessary.

- The control performs very well under all circumstances (also in case of spray tracks, on inclined terrains, etc.), meaning manual intervention is no longer necessary.

- A precise control also improves the harvesting quality

- A potato harvester’s performance is largely determined by an accurate harvesting depth. Harvesting should not be too deep, nor should it be too shallow. The less soil enters the harvester, the less processing is required. This means less load on the machine, resulting in a higher harvesting speed, less wear and a lower fuel consumption per hectare.

- A potato harvester’s performance is largely determined by an accurate harvesting depth. Harvesting should not be too deep, nor should it be too shallow. The less soil enters the harvester, the less processing is required. This means less load on the machine, resulting in a higher harvesting speed, less wear and a lower fuel consumption per hectare.

- Also at higher speeds, the control – and as a consequence the whole machine – remains remarkably stable.

Specifications

Puma 4.0

| Puma 4 | |

| Rows | 4 |

| Inter row distance (cm) | 75 or 90 |

| Dimensions (l x w x h in m) | 15.45 x 3.50 x 4.0 |

| Weight (kg) | 23.500 |

| Bunker capacity (tons) | 8 |

| Maximum discharge height | - |

| Power (hp) | 469 |

| Drive | Hydraulic |

| Offset/in-line | - |

- Solid construction: Compact, lightweight, central chassis beam

- Precise: Precise & ergonomic command

- AVR Connect

- Clear view: Luxurious Claas cabin with automatic functions and excellent view of the harvesting process

- Powerful: Powerful 12.8-liter Stage V Volvo engine that never lets you down. It produces 469 hp, or 1 hp per 50 kg, making the harvester the most powerful in its class. With 30% more front-wheel drive power and 15% more rear-wheel drive power the Puma 4.0 can continue harvesting where others would falter.

- Soft: Potato-friendly, high capacity elevator

- Flexible: Varioweb to be ready for all harvesting conditions

- Instinctive: Oscillating topper, automatically following the ridges

- Light footprint: Lower soil pressure because of large tires (900/60 R38 ‘Very high Flexion Tyres')

- Supple: High wheel radius: 50° in the front and 20° at the back (narrow 300/95 R52 tires)

- Smart: Possible to harvest four- or two-row or convert the digging unit for harvesting carrots or picking up onions.

- Grand: Eight ton bunker for unloading while driving

- Very wet? Easily switch from wheels to tracks in very extreme conditions

- 2,400 mm digging web (x2): driven by means of pitchdependent PUR drive wheels for an increased lifespan and potato-friendliness

- 3,700 mm sieving web (x2): long sieving web, pitchdependent PUR drive wheels with three eccentric vibrators. This web is followed by the first haulm roller.

- 700 mm sieving web (x2): web with double profile rod (rubber rods with pintlebelt profile underneath the retaining rollers). This web is followed by the second haulm roller.

- 1,100 mm full web (x2) for transport towards the Varioweb.

- Varioweb (a combination of a pintlebelt and an axial roller set, in which the axial roller set can be slid continuously out of the product flow), cross roller set or trash web.

- Elevator: heavy-duty rod web with active fingers and PVC cloth coated flights for a product-friendly potato transport.

- Bunker filling belt towards bunker.

- Bunker floor driven independently from elevator (8 ton bunker).

- Elevator with three articulation points; rod web for a massive boost in sieving capacity.

• AVR Connect hardware

• Haulm topper with lateral discharge

• Stage V motor (Volvo), 12,8 l, 345 kW / 469 pk

• Wheel radius front: 50° - back: 20°

• Tire sizes front: 2x 300/95 R52 - back: 2x 900/60 R38

• Side shift on front axle

• Automatic hydraulic level control

• Claas cabin with seat with air suspension, radio, heating, airco

• Two independent, oscillating digging units

• Electro-hydraulic counterpressure control

• Four pulled, plastic diabolos

• Eight pulled, spring-controlled discs

• Two haulm intake rollers

• Two short digging webs with PUR drive wheels

• Two long sieving webs (universal drive) with three eccentric vibrators

• Two rubberized sieving webs with double profi le rod

• 2x2 haulm rollers

• Varioweb (28 axial rollers + pintlebelt)

• Elevator (1,200 mm) with rods, coated with thick star PVC

• Picking-off table (900 mm) with top that can be automatically lowered into the bunker

• Eight ton bunker with elevator (1,650 mm) for unloading while driving

• Truckspot signaling system

• High power LED rear lights

• Active narrowing: digging web to sieving web

• ACC digging unit including AVR Comfort Drive

• Mud flaps

• Adjustable front axle (2.8 -> 3 m and 3 m -> 3.6 m)

• Universal share holders with stone protection

• Extra agitator in digging web

• Automatic inclination correction pintle belt/varioweb

• Cross roller set or solely pintle belt instead of Varioweb

• Electrically foldable and/or adjustable, heated mirrors

• Central lubrication

• Cameras and LED working lights

• Compressor

• Accessories for carrots or onions

• Electrical adjustment of haulm roller Standard

• Autosteer: machine automatically follow the row