Spirit 6200

Spirit 6200

Harvesters

Description

AVR makes 2-row harvesting affordable

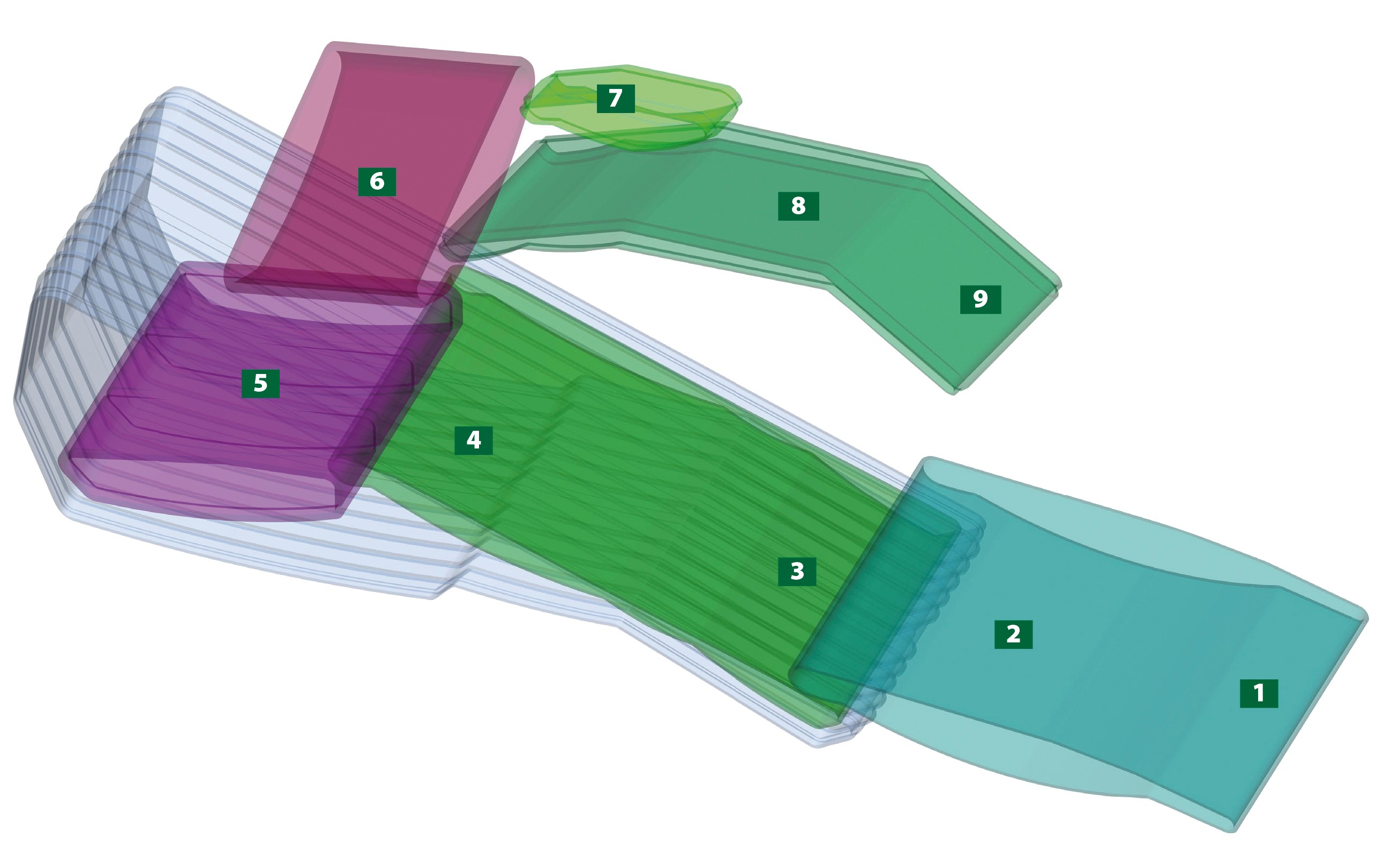

The AVR Spirit 6200 2-row offset bunker harvester offers you exactly what you need: a compact machine that demands little power, is extremely potato friendly and has a high harvesting capacity.

Reliable capacity

This compact 2-row Spirit 6200 offset bunker harvester is highly reliable because of its simple design, and performs spectacularly at the same time. The sophisticated soil separation immediately commences on the digging and sieving web. Subsequently, the efficient haulm web separates the haulm from the tubers, and an in-line pintlebelt removes any remaining loose soil and haulm from the product flow.

A 3-row rotary comb removes stones and clumps from the flow. The flat picking-off table serves as an ergonomic work surface for conducting a final visual inspection. The product flow is then led to the spacious bunker. Once the bunker is full, it can be emptied in under a minute using the quick unloading floor.

Specifications

Spirit 6200

| Spirit 6200 | |

| Rows | 2 |

| Inter row distance (cm) | 75 or 90 |

| Dimensions (l x w x h in m) | 9.83 x 3.30 x 3.80 |

| Weight (kg) | 8.370 |

| Bunker capacity (tons) | 6 |

| Maximum discharge height | 4.20 |

| Required power (hp) | 66 kW / 90 hp |

| Drive | Mechanic |

| Offset/in-line | Offset |

| Oil flow (on 180 bar) (l/min) | 60 (75 if WB option) |

- 1.65 m wide sieving webs

- Haulm web for an efficient haulm separation

- Large platform around picking-off table with room for up to 6 people

- Operation by means of a structured display and joystick (can-bus system)

- Optionally available WB bunker, 5.5 ton buffer and elevator with 3 articulation points -> capacity raise of at least 15%

- Open construction, easily accessible for maintenance

- Plastic diabolos run precisely along the row and determine the harvesting depth. The plastic material reduces soil clogging and is stone-resistant. Large haulm intake rollers and cutting discs prevent haulm blockages. The harvesting depth can easily be adjusted using a central crank spindle. An accumulator and optional electro-hydraulic ground pressure control system ensure minimal pressure on the row.

- The digging web is 1,650 mm wide and comes standard with two star vibrators that are operated hydraulically from the tractor. The web is driven by highly durable and potato-friendly PUR drivewheels.

- The product flow falls from a minimal height onto the second sieving web, where most of the soil is removed.

- A haulm web is mounted above the second sieving web. This web makes sure the haulm is efficiently and carefully separated from the potatoes. This system is also ideally suited for harvesting while the haulm is still green. Haulm pallets guarantee the potatoes cannot fall behind the harvester.

- The product flow then reaches the in-line pintlebelt where soil, small clods of earth and haulm are removed.

- The retaining rollers guide the flow to the transversal pintle belt, above which a rotary comb is mounted that efficiently separates clods and stones from the potatoes. The clods and stones land on top of the discharge belt, where a collapsible platform serves as an extra control post for two persons.

- The potato flow reaches the picking-off table, where there is room for four people to execute a final visual inspection. AVR made sure the work space is large enough to be able to work ergonomically.

- The top of the picking-off table lowers into the bunker, where a sensor minimises the drop height.

- 2 speed gear-box

- PTO drive shaft 540 rpm

- independent hydraulic system with LS pump for pintlebelt, retaining roller and rotary comb drive

- wheels 700/50 - 26.5

- hydraulic steering wheels (+/- 24°) with automatic centering

- hydraulic land levelling

- automatic row following (drawbar control)

- swinging digging unit

- 4 pulled, spring loaded discs

- 2 pulled, plastic diabolo rollers

- 2 large haulm intake rollers (400 mm)

- counterpressure control on digging unit with accumulator

- digging web with PUR drivewheels

- hydraulically adjustable star vibrators

- electro-hydraulic angle adjustment of pintlebelts

- 3-row rotary comb

- picking-off table for 4 persons (900 mm wide) with control box

- discharge belt with room for 2 extra persons

- steering via CAN-bus system, with joystick and graphic display in cabin

- 6 ton bunker with double bunker lift

- retaining rollers 2 x 2 rows rotary comb / brush

- universal share holder with stone protection

- extra disc on the outer right side

- maximum bunker fill (rubber sheet)

- shock absorber (crate filling) (hydr./mech.)

- automatic land levelling

- electro-hydraulic counterpressure control on diabolos

- automatic swan neck picking-off table

- electrical adjustment of rotary comb

- pintlebelt boost

- cameras

- onion picking unit

- onion harvesting unit

- carrot unit with torpedoes

- automatic sliding of bunker floor

- stone box under picking-off table

- half diabolos for bed harvest

- hecctare counter